Reference: ZWEAF-N

Brand: ZWO

Reference: ZWEAF-N

Brand: ZWO

Reference: POA-URANUS-C

Brand: Player One

Reference: POA-ACS

Brand: Player One

Reference: AS-FRA400

Brand: ASKAR - Sharpstar

Reference: ZWASI120MINI

Brand: ZWO

Reference: AS-SET-DUO-D1D2

Brand: ASKAR - Sharpstar

Reference: ZWDC-Y-SPLIT

Brand: ZWO

Reference: AS-REDFRA400

Brand: ASKAR - Sharpstar

Banner

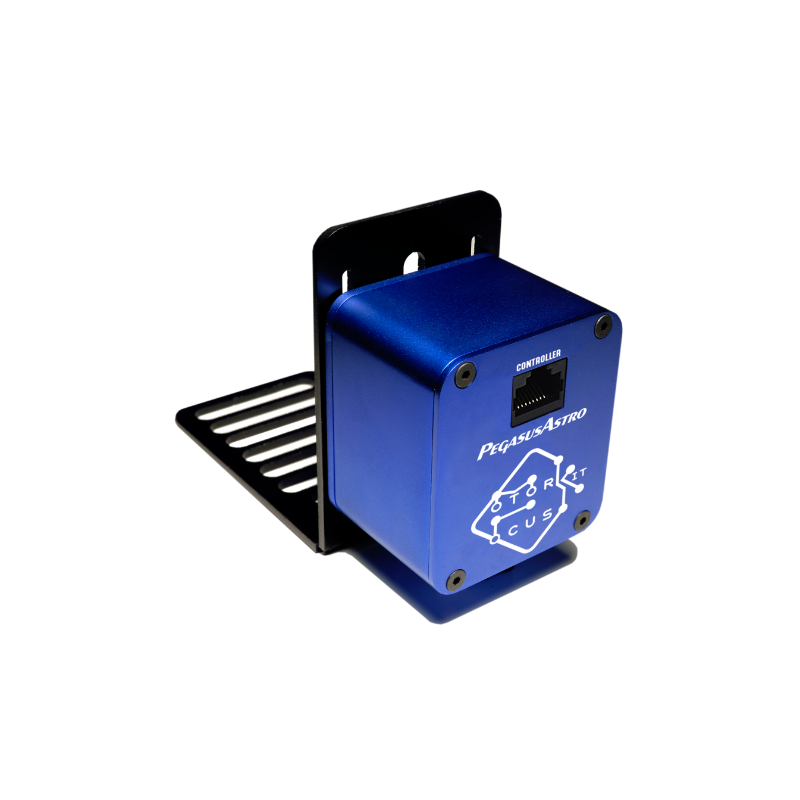

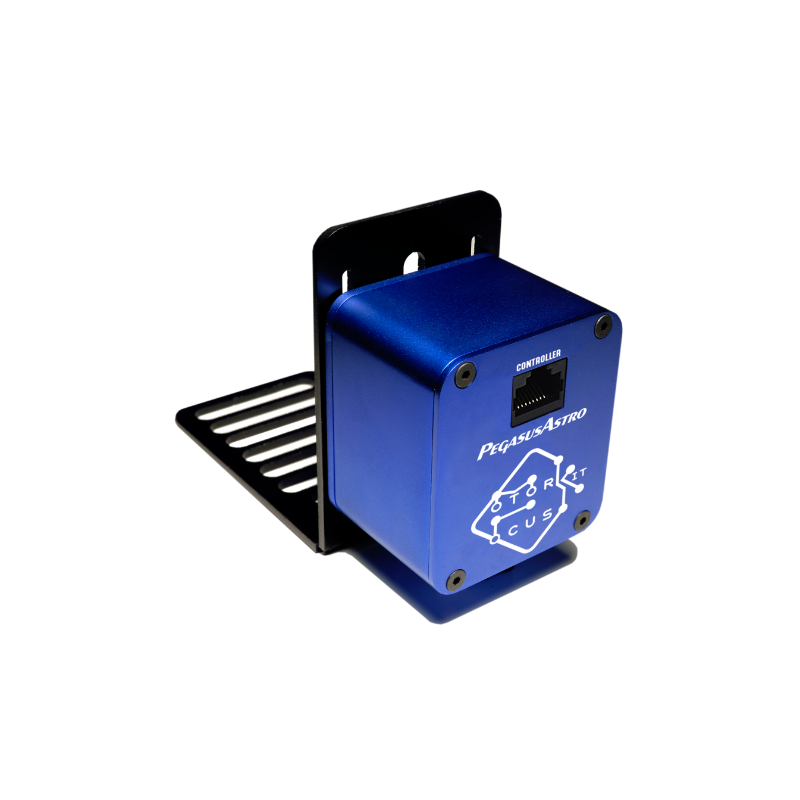

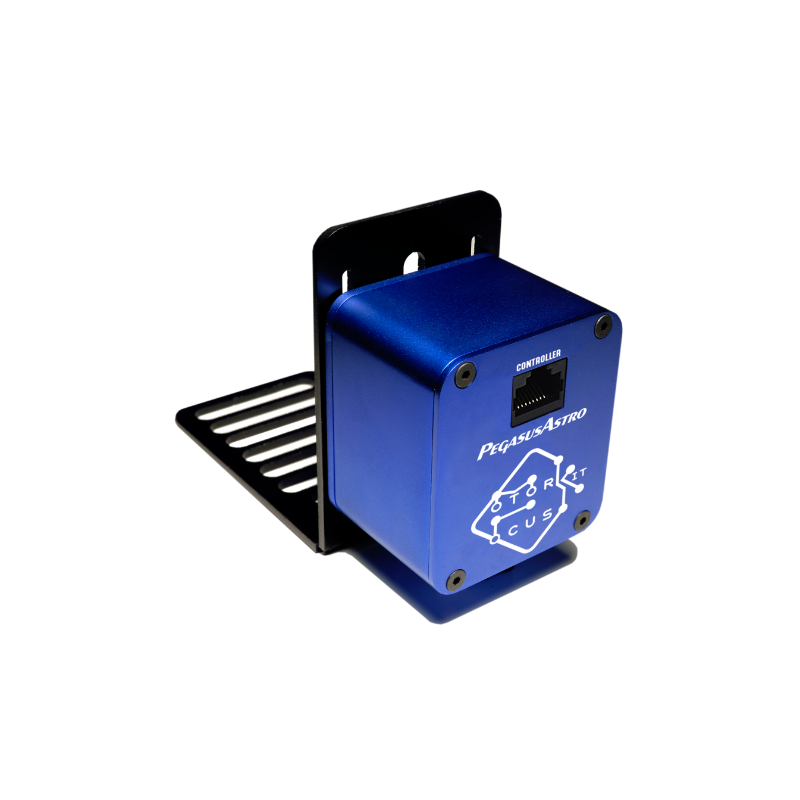

PegasusAstro Universal Focus Motor

security

security

100% Secure Payment

Delivery policy

Delivery policy

Express shipping of in-stock parts

RETURN POLICY

RETURN POLICY

Express shipping of in-stock parts

Focus your telescope accurately and quickly using our powerful V2 motor focuser kit. This 0.06 degree high resolution box can easily lift over 6 kg (per cm).

Its high torque is suitable for heavy imaging equipment. Additionally, the motor gearbox has low backlash which can easily be adjusted using backlash compensation in the imaging software.

The RJ45 socket can be converted to a Robofocus type serial port easily.

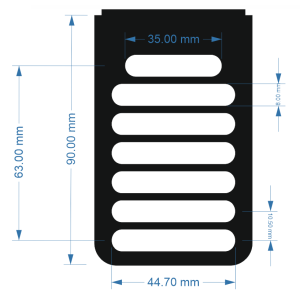

A rigid L-shaped black anodized aluminum bracket has cut rails and can be attached to a wide range of focusers. this support has been successfully tested on the following eyepiece holders:

This Focus motorcycle can only be controlled through 2 solutions:

The advantage over its USB version is that this motor receives its power and control via a single cable, unlike the USB version which must be connected to a 12V power supply in addition to its USB port and probe.

Thus it is the ultimate power box which will provide the power and the orders of movements by the ticket of a computer. Less cable!

This Moto focus can also be used without the powerbox but it will need to be paired with an additional external controller.

✅ We recommend this Motofocus for pure imager systems in addition to the solution with the ultimate powerbox!

✅ Software and driver download: https://pegasusastro.com/support/

En venant de chez ZWO, je trouve que ce Moteur à vraiment peu de jeu de fonctionnement, et les pas sont plus fin du coup la précision de mise au point est plus efficace

Reference: PEG-FC-HC

Brand: Pegasusastro

Reference: EAF-TSFOCR30

Brand: TSOptics

Reference: PEG-PRDG-FOCUSER

Brand: Pegasusastro

Reference: AS-KIT-ACL200

Brand: ASKAR - Sharpstar

Reference: PEG-LENS-KIT

Brand: Pegasusastro

Reference: PEG-MFKZERO-SCT11

Brand: Pegasusastro

Reference: PEG-FCZERO-SCT68925

Brand: Pegasusastro

Reference: SESTOSENSOII

Brand: PrimaluceLAB

Reference: PEG-FC3-UNIV

Brand: Pegasusastro

Reference: ZWEAF-SENSOR

Brand: ZWO

Reference: ZWEAF-C8-C925

Brand: ZWO

Reference: EAF-M2G2

Brand: TSOptics

Reference: PEG-SCT68925-KIT

Brand: Pegasusastro

Reference: ZWEAF-BRK-TK

Brand: ZWO

Reference: PEG-FCZERO-SCT11

Brand: Pegasusastro

Reference: SESTOSENSO3

Brand: PrimaluceLAB

PegasusAstro Universal Focus Motor

check_circle

check_circle